CAPABILITIES

More than a parts supplier—we’re your manufacturing partner.

We help you solve design challenges, scale production, and meet deadlines with confidence—on time, on spec, and without added friction.

Manufacturing Assessments

Evaluate early. Avoid costly fixes.

Whether you're developing a new product or scaling an existing production line, we offer structured manufacturing assessments that help you optimize processes, improve design, and reduce costly rework.

With nearly two decades of experience in automation and tooling, Bent River guides you through targeted evaluations with clear phases, concrete deliverables, and ROI-backed recommendations.

-

Make your product easier (and cheaper) to build—before it hits the floor.

After years of watching customers go through costly re-designs, we developed a process that identifies and enhances the manufacturability of new products before they go into production.

Phases:

Assess & explore

Brainstorm & ideate

Prioritize impact

Deliverables:

Detailed report of findings

-

Validate your production process and uncover ways to do it better.

Gain the competitive advantage in meeting customer demands with a long-term strategy for implementing manufacturing technology. We look at your entire line—from equipment layout to data flow—to identify opportunities for automation, cost reduction, standardization, and performance gains.

This assessment is ideal for teams looking to modernize production, reduce downtime, and align with SCADA, MES, or ERP systems.

Phases:

Assess & explore

Develop & analyze

Get results

Deliverables:

Three year manufacturing equipment and process plan

Estimated ROI on equipment enhancements

Future state value stream map

Future state KPIs and expected performance.

Want fewer surprises and stronger margins?

Engineering & Prototyping

From idea to engineered system.

Are you developing a new automation line or refining a complex tool? Our in-house engineering team is dedicated to ensuring your machine runs with precision, reliability, and clarity—on paper and the floor.

From concept through final layout, we design the systems that power every build, with constant communication between our mechanical, electrical, and controls teams.

The result: a fully engineered solution that’s ready to run.

-

Mechanisms that work — built to spec, designed to scale, and ready for production.

Complete system design, from parts to final assembly

In-house prototyping and real-world testing

CAD expertise in Creo and SOLIDWORKS

Clear, build-ready documentation

Fast feedback to keep things moving

-

Motion that’s smart, reliable, and dialed into your process.

Custom motion and logic designed to match your exact needs

PLC configuration on a range of platforms including WAGO and Code Assist

HMI programming for optimal user experience

Controls integrated early in the design phase

-

Clean, efficient power and control — laid out to simplify design and build.

Custom schematics showing full electrical flow and logic

Power, safety, and control blocks designed for clarity

A proven layout method that speeds up the design phase

Designed with serviceability and reliability in mind

Need a team that designs with execution in mind?

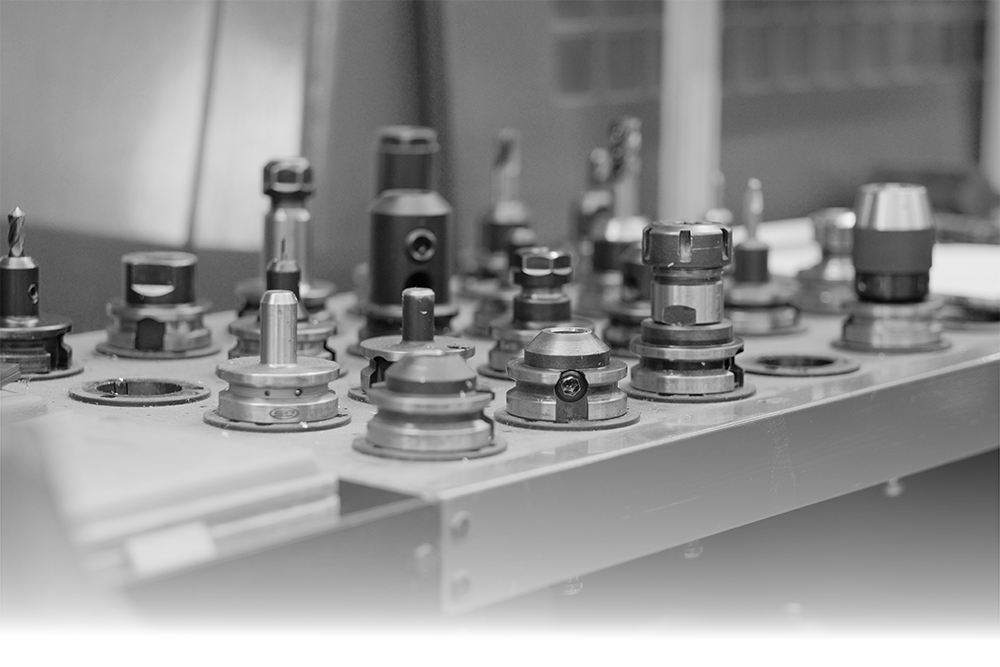

Machining & Fabrication

Where design becomes real.

Need precision parts, quick-turn prototypes, or custom assemblies? Our fabrication team delivers production-quality work, every time.

With in-house CNC mills, lathes, manual machines, and tight integration with our engineering team, we bring your designs to life.

-

Parts arrive right the first time — built to your spec, reviewed by engineers, and ready for use on the floor.

CNC and manual machining under one roof

Skilled machinists who collaborate directly with engineers

Rapid prototyping and short-run production

Mechanical assembly and fit checks built into the process

Shop-floor flexibility for last-minute adjustments or changes

Parts delivered to print — tight tolerances, consistent quality

ISO 9001:2015-certified processes and inspections

-

CNC Mills

HAAS VF-6SS X64 Y32 Z30

HAAS VF-3YT X40 Y26 Z25

HAAS VF-3YBT X40 Y26 Z25

HAAS VF-3SS X40 Y20 Z25

HAAS VF-2SS X30 Y16 Z20

Mastuura RA3 X31 Y17 Z14

Mastuura 510 Vertical

CNC Lathes

HAAS ST-20 CNC Lathe

Hitachi-Sieki HT-20 CNC Lathe

Manual Equipment

3 Manual Mills X31 Y14 Z24

Harding Tooling Lathe

Harig Surface Grinder

Horizontal & Vertical Band Saws

Fabrication

CNC Plasma X48 Y96 Z1

15 Ton Press Brake – Y 121 Z0.875

Shear – 1/8”

Welding – MIG & TIG

Welders currently certified to AWS D1.1 and D1.6

Certified Welding Inspector on-site for additional certs

Finishing & Inspection

Vibratory Polisher

Engraved Labels, Tags

Need tight-tolerance parts without the delays?

Mechanical & Electrical Assembly

Assembled with precision. Backed by experience.

Tired of chasing down fit issues or wiring mistakes during install? We solve that upfront. Our team delivers production-ready assemblies that are built to spec, tested for fit and function, and ready to drop into place.

From mechanical builds to electrical panels, we handle it all in-house — with tight coordination between teams.

-

From first part to final handoff, our process is built to deliver a smooth experience — clear communication, no surprises, and a system that’s ready to run.

Process:

Source Materials

We procure all raw materials and components, whether we’re building from your design or ours.Fabricate Parts

Mechanical parts are machined in-house using CNC mills, lathes, and sheet metal tools. Finishing services are coordinated as needed.Assemble & Integrate

Our team assembles the mechanical structure and installs electrical components like PLCs, sensors, and power supplies per the prints.Wire & Plumb

We route all wiring to field devices and build pneumatic systems with regulators, valves, and cylinders as needed.Test & Validate

We perform I/O checkout, functional testing, and hand off to controls for HMI or motion logic where required. UL certification available.

Need an assembly team that owns the full build?

Automation & Integration

Custom systems. No compromises.

Do your requirements fall outside the industry standard? We design and build what others can’t — fully integrated, custom automation that’s designed to fit your space, your specs, and your production goals.

Whether you're starting from a napkin sketch or refining a production line, we help move the system forward without sacrificing performance or flexibility.

-

Flexible Production

Automate repetitive tasks to reduce error and easily scale output.

Custom Processes

We design the right mix of automated machines, conveyors, fixtures, and motion control equipment to match your workflow, facility, and specifications.Efficiency Without the Waste

Integrated systems speed up manufacturing, inspection, and testing while minimizing downtime and scrap.Low-Maintenance by Design

We engineer for reliability, so your system runs longer with less intervention.Support Through Change

As your needs evolve, we stay with the build — adapting systems, scaling parts, and keeping production moving.

-

Boost productivity, improve consistency, and reduce cost — our automation systems are built to make your line faster, safer, and more reliable at every step.

Material handling

Palletizing

Pick and place

Case packing

Machine tending

Automated assembly

Vision-guided bin picking

Is your system too complex for off-the-shelf solutions?

Value-Added Services

Fewer vendors. Lower total cost.

Still chasing parts through multiple vendors? When finishing and inspection are handled separately, small delays stack up fast.

We manage the full process in-house or through trusted partners — so your parts arrive complete, compliant, and ready for install.

-

Smoother builds start with the right parts at the right time.

All fasteners, motors, valves, chains, breakers, and fittings sourced to spec

Reduce lead time through centralized sourcing

One point of contact for materials and components

-

Avoid juggling vendors or chasing quotes — subcontracted work is fully managed.

Access to qualified, pre-vetted partners

Ongoing tracking of quality and delivery performance

Weekly reviews to make adjustments as needed

Monthly audits to prevent systemic problems before they impact your schedule

Frees up your team to focus on core competencies

-

Get specialty finishing and testing without the runaround.

Heat treatment

Destructive and non-destructive testing

Surface prep, plating, and finishing

EDM, grinding, and honing

Need fewer vendors—and more progress?