Optimize your facility’s manufacturing operations with custom factory equipment designed for your specific processes. Bent River specializes in helping companies customize their factory machinery to match their products, production styles, and business goals. Our end-to-end build-to-print machinery services include simple tooling production, fabrication, assembly, and testing. Learn more about our machinery build processes and capabilities to determine the level of customization that’s right for your needs.

About Custom Factory Equipment

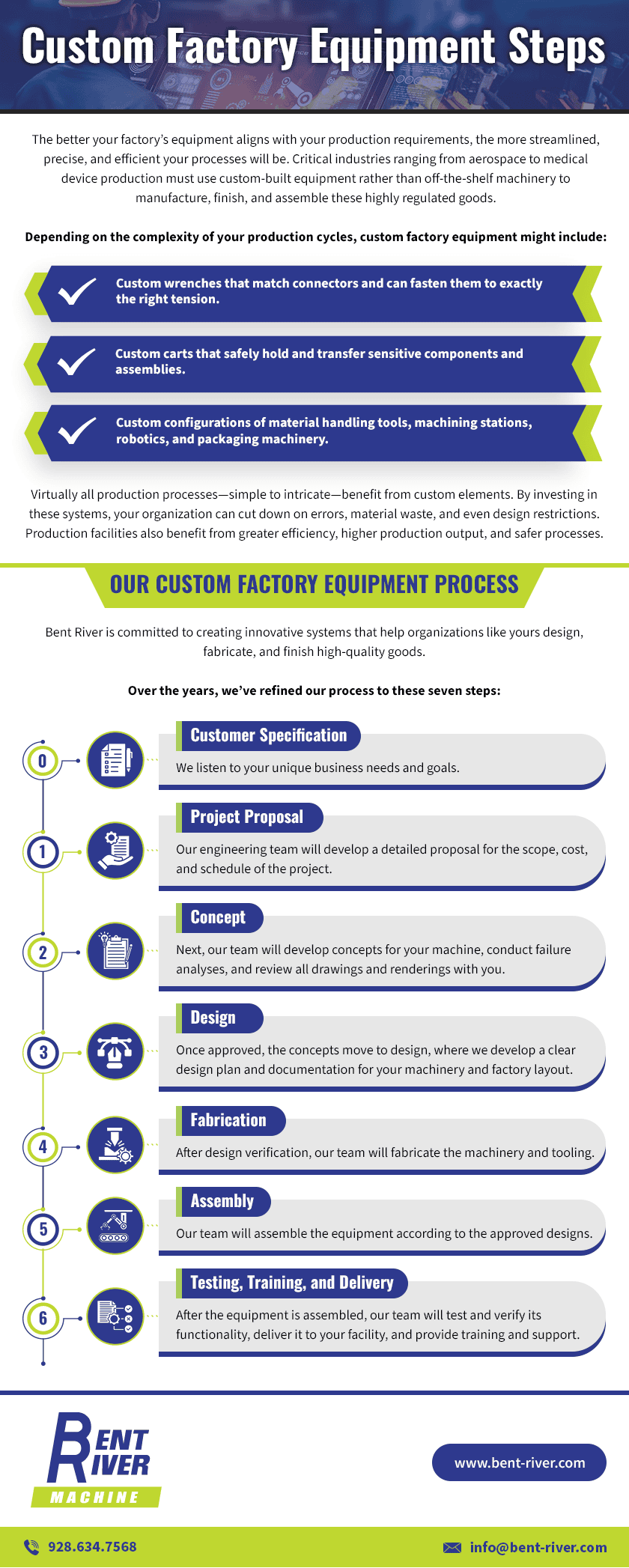

The better your factory’s equipment aligns with your production requirements, the more streamlined, precise, and efficient your processes will be. Critical industries ranging from aerospace to medical device production must use custom-built equipment rather than off-the-shelf machinery to manufacture, finish, and assemble these highly regulated goods.

Depending on the complexity of your production cycles, custom factory equipment might include:

- Custom wrenches that match connectors and can fasten them to exactly the right tension

- Custom carts that safely hold and transfer sensitive components and assemblies

- Custom configurations of material handling tools, machining stations, robotics, and packaging machinery

Virtually all production processes—simple to intricate—benefit from custom elements. By investing in these systems, your organization can cut down on errors, material waste, and even design restrictions. Production facilities also benefit from greater efficiency, higher production output, and safer processes.

Importance of Custom Factory Equipment

Custom factory equipment can satisfy the needs of multiple operations housed within a single factory. These systems can handle virtually every stage of fabrication, finishing, packaging, and sorting for distribution. Build-to-print machinery and custom factory systems from Bent River offer many advantages over standard solutions.

Efficiency

Our design and engineering team can assess your current production processes and machinery needs to create systems that better match the individual steps within the process. This can include building machinery that requires fewer steps or discrete motions, faster conveyor belts, and more compact layouts so there is less wasted floor space. For example, custom machinery can be quickly adjusted to produce different product SKUs with a simple tooling changeout.

Safety

With custom machinery, your technicians make fewer manual adjustments. As a result, there are fewer interactions with sharp or heavy equipment. We also design custom machinery that complies with government and industry-specific regulations, as well as equipment with ergonomic considerations and better vibration and noise ratings.

Accuracy

Whether your organization specializes in complex assemblies or small high-volume components, most products need to meet design requirements within extremely tight tolerances. Custom factory equipment maximizes quality by increasing precision and accuracy. You can meet production goals more efficiently, minimize errors and waste, and boost long-term profit.

Our Custom Factory Equipment Process

Bent River is committed to creating innovative systems that help organizations like yours design, fabricate, and finish high-quality goods. Over the years, we’ve refined our process to these seven steps:

- Step 0—Customer Specification. We listen to your unique business needs and goals.

- Step 1—Project Proposal. Our engineering team will develop a detailed proposal for the scope, cost, and schedule of the project.

- Step 2—Concept. Next, our team will develop concepts for your machine, conduct failure analyses, and review all drawings and renderings with you.

- Step 3—Design. Once approved, the concepts move to design, where we develop a clear design plan and documentation for your machinery and factory layout.

- Step 4—Fabrication. After design verification, our team will fabricate the machinery and tooling.

- Step 5—Assembly. Our team will assemble the equipment according to the approved designs.

- Step 6—Testing, Training, and Delivery. After the equipment is assembled, our team will test and verify its functionality, deliver it to your facility, and provide training and support.

Custom Factory Equipment by Bent River

Get custom factory equipment built to get the job done right with Bent River Machine. Our organization is ISO 9001:2015 certified, and we work with each of our clients to provide state-of-the-art automated systems that align with their project and quality control needs. For over 40 years, we have been bringing complex concepts to life for our customers through collaborative consulting, engineering, integration, and ground support.

Contact us today to discuss your custom factory machinery needs, or request a quote to start your build.