Solar Panel Lamination Process Explained

Comments Off on Solar Panel Lamination Process ExplainedOne of the most important processes in solar panel manufacturing is lamination. During lamination, solar cells are sandwiched between two or more protective layers of material. Solar cells are vulnerable to moisture and mechanical damage, so these protective layers help prevent damage from tree branches, debris, UV exposure, and the elements.

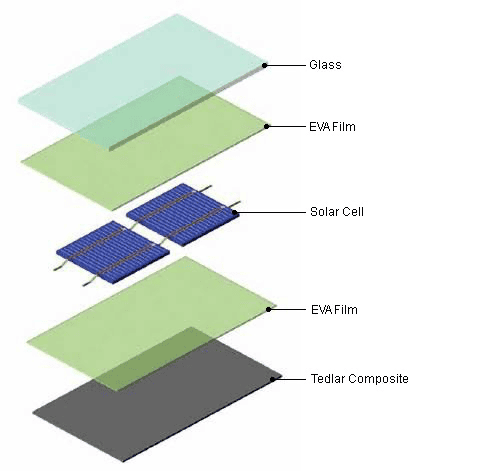

A typical lamination stack-up includes ethylene-vinyl acetate (EVA) encapsulant layers, a back sheet, and a front cover glass. The laminated solar panel is a photovoltaic (PV) module that can resist long-term weather exposure without sacrificing energy generation efficiency. Learn more about the solar panel lamination process, its benefits, and the unique value of Bent River’s photovoltaic module laminator.

Why Solar Panel Lamination Is Important

Solar cells efficiently convert solar energy into electrical energy for collection, on-site use, or transmission to the connected energy distribution system. However, the thin, wafer-like cells are fragile and can be damaged by debris, hail, and other physical forces. PV module laminators are important because they provide a durable layer of defense against these destructive elements. Some of the key reasons why manufacturers prioritize high-quality lamination are:

- Investing in durable lamination will extend the overall lifespan of the solar cells.

- Lamination will maintain the energy conversion efficiency of the cells.

- Lamination locks out water, which preserves the cells and prevents corrosion.

The Solar Panel Lamination Process

Solar panel lamination generally follows these steps:

- The solar panel lamination process begins with positioning solar cell between layers of EVA, a front cover glass, and a back sheet like Tedlar Polyester Tedlar (TPT). This creates a typical five-layer PV module.

- A vacuum is applied to the module to remove air from the vacuum chamber and to prevent voids in the laminations.

- Heat and pressure are applied to the module based on the input material and its cure temperature and time, typically 135 °C (275 °F) for 7-10 minutes.

- The panel is carefully cooled to solidify the laminations.

- Manufacturers cut away extra EVA and TPT material, so the resulting module has clean, squared edges.

- Finally, the modules are outfitted with a junction box and framed.

Benefits of the PV Module Lamination Process

PV module lamination ensures the energy efficiency and structural integrity of the solar panel. High-quality lamination can reliably protect the cells from environmental degradation and physical damage for at least 25 years. The process also improves the panels’ electrical insulation, lowering the risk of short-circuiting and electrical faults. Ultimately, the higher the quality of the lamination process, the better the final product will perform.

Choose Solar Panel Laminators From Bent River

At Bent River, we have been designing and building solar panel laminators since 2008. Our laminators are designed to create high-quality panels that last for decades. We help customers solve common lamination problems, such as air entrapment, process instability, deformation, and more. Leading manufacturers throughout the space and terrestrial solar industries rely on Bent River for the consistent quality of our laminator equipment.

Over the years, we have optimized our laminator equipment with new technologies, such as a PIN mechanism to keep the product from the heat source until ready, enhanced HMI controls for customization, and bi-directional membrane control for product stabilization. For each new project, we develop a tailored process guide based on the client’s lamination materials and pressure, heat, and time variables. This process guide is designed to maximize the repeatability and efficiency of your lamination process.

Request a quote to learn more about our lamination equipment.